ERG 001 - Optimization of the production plant with our tube winders

Overview Engineering Reports Graf Technical supportInitial situation

The family managed packaging company is focused on spiral sleeves for the food and industrial companies. Tube winding systems are operated at two plants in Austria and are manufactured around the clock in order to meet the predominantly national demand.

Task

The operating technology has been boothering for several years due the time-consuming and precision-required placement of the wear belts for the tube winding machines. The tube winding belts supplied and installed by the system manufacturer are stiff, unwieldy and have a qualitatively fluctuating wear depending on material thickness. Their search for a european manufacturer of high-quality tube winding belts brought him to the nearby Dipl. Ing. Werner Graf AG.

Solution

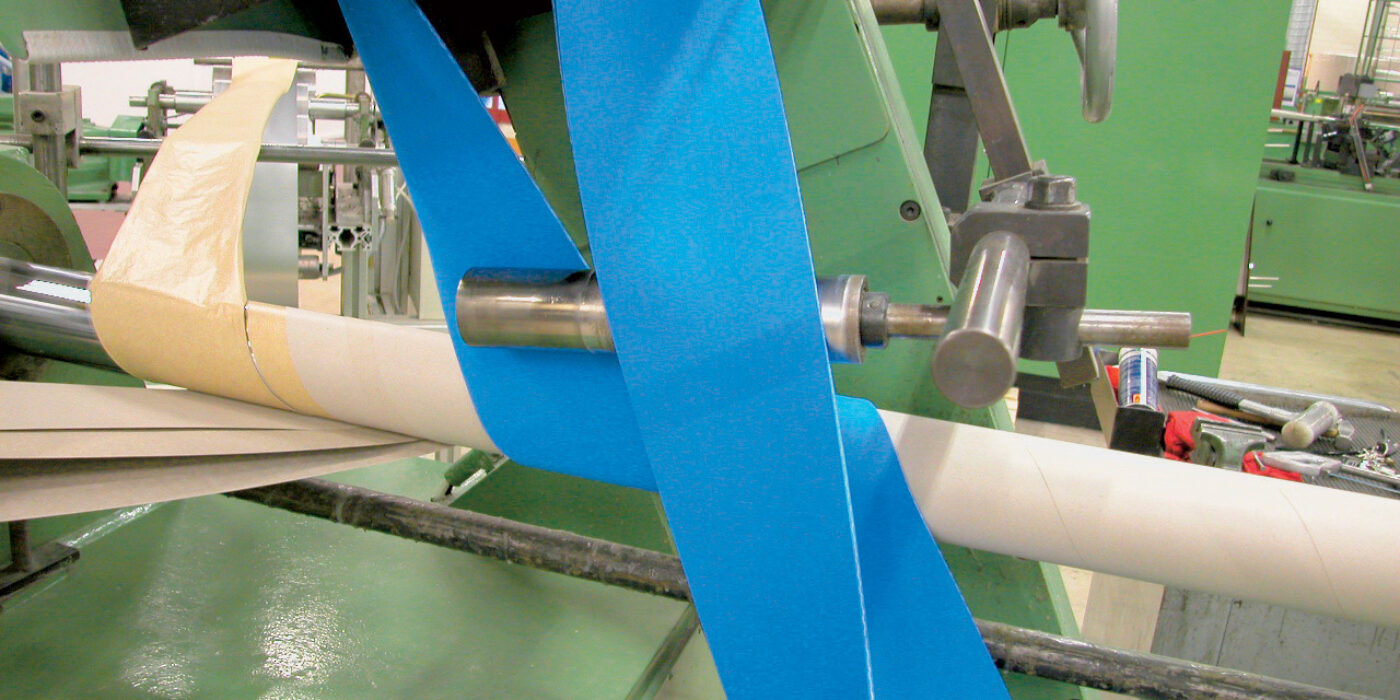

With our classic, developed for the tube winding Industry, the HEVALOID endless tube winding belt consisting of endless woven polyester yarns and the highest rubber quality, we convince immediately in terms of flexural flexibility and ease of assembly. Only in the course of the conversion to our Hevaloid 568 TW blue comes the full signification to light:

- easier and faster installation of our tube winding belts

- increased life time up to 65% due to highest abrasion resistance

- maximizing precision in the tube winding process